Designed for Power, Precision, and Reliability

At DELLNER HYDRATECH, our piston accumulators are designed for exceptional performance, providing reliable energy storage, emergency backup, and precise pressure control for hydraulic systems. Crafted from durable materials and utilizing advanced sealing technology, these accumulators guarantee long-lasting efficiency, even in the most challenging industrial environments.

Customized Manufacturing

DELLNER HYDRATECH's piston accumulators are perfect for fluid power management, shock absorption, and maintaining system stability. Our customizable piston accumulators can be tailored to your specific requirements, boosting productivity while reducing maintenance needs.

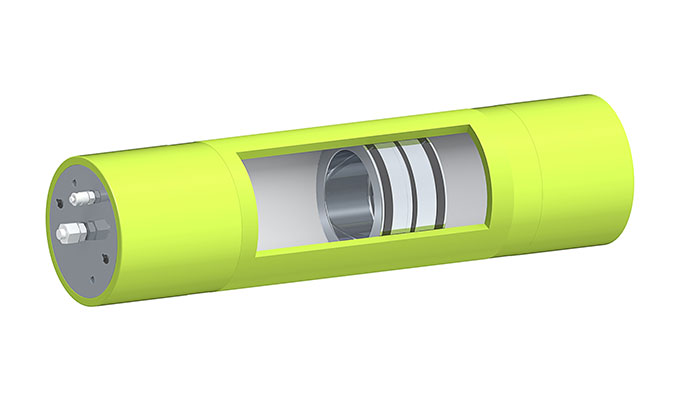

Piston Accumulators

Piston Accumulator

HYDRAULIC SYSTEMSDesigned for use in Hydraulic Systems for energy storage, emergency backup, dampening of pump pulsations, flow stablizing, and shock absorbing.

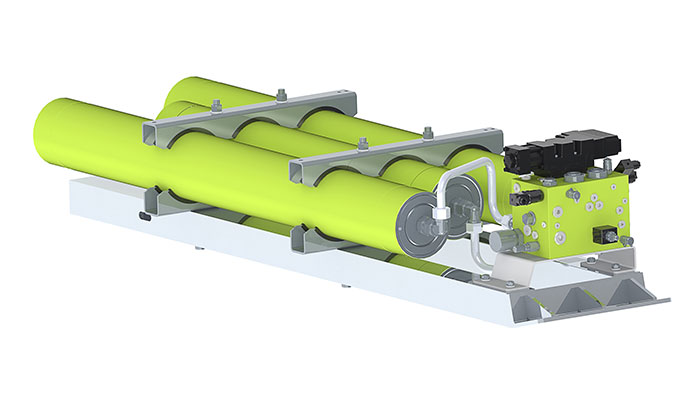

Request InfoPiston Accumulator Module

HYDRAULIC SYSTEMSHydraulic accumulator modules serve as the energy storage devices within hydraulic systems, playing a vital role in maintaining system stability and efficiency.

Request Info

Achieving industry certifications reflects our commitment to exceptional manufacturing, ensuring the highest standards of quality, precision, and innovation in every product we deliver.

- PED

- ASME

- SELO

- No. 13

- DNVGL

- ABS

Repair, Overhaul, Inspect & Upgrade

DELLNER HYDRATECH is committed to maintaining the quality and performance of our manufactured products through expert repair, inspections, complete overhauls, and strategic upgrades. Our dedicated team ensures that each product continues to meet industry standards, enhancing reliability, efficiency, and longevity, maximizing your investment.